Read Kevin’s previous post here.

Now that the hard work is done, it is time to focus on the finishing touches. Ever since I decided to finish the basement this spring, I would spend time in the basement trying to imagine what the finished product would look and feel like. What were the little touches that would separate it from every other quick and dirty finish job, instead making it a space that could be a sanctuary, somewhere I could be proud to host a poker night or Super Bowl party. All of that comes down to those little touches that make a space become a room.

The easy decisions were with the base boards. I want to do my best to match the rest of the house in elegance, but the trim in the rest of the house is more than six and a half inches tall, and in the basement where ceilings are seven feet or less, that would be too visually distracting. So for the carpeted area I went with 1×4 boards with a half inch OG molding on top, and for where the hardwood area the same 1×4 and OG with shoe molding. For all the baseboards I went with clear pine, which is pine without knots. And I choose to match the built in cabinet in color and used a natural cherry stain, and a matte finish clear coat.

To try and make the basement feel like a part of the rest of the house, when I was doing the staining I tried to not be perfect. No big mess ups, but just enough imperfections to give the wood a weathered and slightly aged look. I did this by brushing the stain on a little thicker, letting it start to dry for about 10 minutes, and then brushing it down a little more to smooth it out, but not so much that it looked crisp.

Another neat finishing touch was the window treatments. Because they are basement windows they have very deep sills, and since the brick work wasn’t the best, we decided to make 12 inch deep shadow boxes, this time using birch. Birch has a similar grain to pine, so it will match the rest of the room, but it is more durable and better suited to be near the temperature fluctuations of windows. There were originally two windows on the front wall of the house, but one was under the front porch, so we bricked that up, but kept the window space to turn it into another shadow box for balance. Near the middle of the room at the support beam, we had to build the wall thicker because the beam was thick and crooked, but it gave us the opportunity to build another shadow box that is only five inches deep, but helps balance the room. All of these were stained cherry like the trim.

Continues after the jump.

The last project of the weekend was searching for doors. I need three, one for the bathroom/laundry room, one to the utility room area, and one for access to the AC compressor. I priced out new doors, but it came to nearly $400 per door since they would all have to be custom made, and that is just too much money for three doors. So on Mother’s Day I took a trip out to Community Forklift with my mother and father, and after searching through hundreds of old doors, we found two five-panel doors that matched the original house and would fit perfectly, as well as a louvered door that will fit the access to the AC compressor perfectly and provide the air circulation it needs. All three doors came to $55 total. We will need to custom build door jambs and trim, and have the doors stripped so they can be stained, but it will still be a huge money saver. Plus I will have period correct doors that will further tie the room to the rest of the house and help make it feel like it’s been there since the beginning.

So my goal of finishing in just 4 weekends is not going to happen. Some scheduling issues slowed us down a bit, and I am leaving for a two week vacation starting today. So there will not be an update next two weeks, but after I get back I should be able to give the final post talking about the new stairs and the floating floor and any last details.

Do you have any experiences in trim work or finding treasures at a salvaged goods store?

More pictures here.

Recent Stories

Photo by Beau Finley Ed. Note: If this was you, please email [email protected] so I can put you in touch with OP. “Dear PoPville, Him, dapper chap with a light…

For many remote workers, a messy home is distracting.

You’re getting pulled into meetings, and your unread emails keep ticking up. But you can’t focus because pet hair tumbleweeds keep floating across the floor, your desk has a fine layer of dust and you keep your video off in meetings so no one sees the chaos behind you.

It’s no secret a dirty home is distracting and even adds stress to your life. And who has the energy to clean after work? That’s why it’s smart to enlist the help of professionals, like Well-Paid Maids.

Unlock Peace of Mind for Your Family! Join our FREE Estate Planning Webinar for Parents.

🗓️ Date: April 25, 2024

🕗 Time: 8:00 p.m.

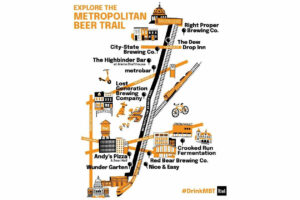

Metropolitan Beer Trail Passport

The Metropolitan Beer Trail free passport links 11 of Washington, DC’s most popular local craft breweries and bars. Starting on April 27 – December 31, 2024, Metropolitan Beer Trail passport holders will earn 100 points when checking in at the

DC Day of Archaeology Festival

The annual DC Day of Archaeology Festival gathers archaeologists from Washington, DC, Maryland, and Virginia together to talk about our local history and heritage. Talk to archaeologists in person and learn more about archaeological science and the past of our