Kegerator Repair Service

“I realize that this may be a super specific request, but multiple Google searches didn’t help, so in my darkest hour of need I turn to the good people of Popville! I recently finished building my DIY kegerator and it looks beautiful and runs lovely, just having some issues with foaming. I’ve called a few refrigeration companies, but the fridge itself works great. I will be asking some of my local drinking establishments tonight, but thought that if anyone knew of a company or guy that could help me with my issues (as I’ve attempting to fix it all from the standard “what’s wrong with it” from troubleshooting. Would love to have this good to go for my 4th of July BBQ, but clearly that may be pushing it at this point. Thanks so much for any insight you may have!”

You can see all forum topics and add your own here. If you are having trouble uploading your question please email me at princeofpetworth(at)gmail Please Note this is NOT an events calendar.

Recent Stories

Photo by Beau Finley Ed. Note: If this was you, please email [email protected] so I can put you in touch with OP. “Dear PoPville, Him, dapper chap with a light…

For many remote workers, a messy home is distracting.

You’re getting pulled into meetings, and your unread emails keep ticking up. But you can’t focus because pet hair tumbleweeds keep floating across the floor, your desk has a fine layer of dust and you keep your video off in meetings so no one sees the chaos behind you.

It’s no secret a dirty home is distracting and even adds stress to your life. And who has the energy to clean after work? That’s why it’s smart to enlist the help of professionals, like Well-Paid Maids.

Unlock Peace of Mind for Your Family! Join our FREE Estate Planning Webinar for Parents.

🗓️ Date: April 25, 2024

🕗 Time: 8:00 p.m.

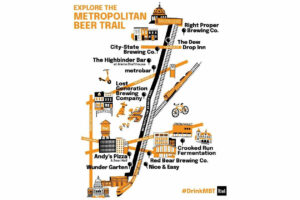

Metropolitan Beer Trail Passport

The Metropolitan Beer Trail free passport links 11 of Washington, DC’s most popular local craft breweries and bars. Starting on April 27 – December 31, 2024, Metropolitan Beer Trail passport holders will earn 100 points when checking in at the

DC Day of Archaeology Festival

The annual DC Day of Archaeology Festival gathers archaeologists from Washington, DC, Maryland, and Virginia together to talk about our local history and heritage. Talk to archaeologists in person and learn more about archaeological science and the past of our